You may be reviewing our Website to consider Specdrums manufacturing capability and capacity to fulfil your Drive Drum and Tail Drum requirements for the Belt Conveyors your business manufactures.

We understand that if you are business that manufactures many of the same drums, on a regular basis that there a number of KPI’s which must be met:

Manufacturing Capability:

- Pipe Diameters: 90mm Dia Up to 813mm Diameter

- Pipe Lengths: 200mm Up to 3000mm Length

- Shaft Diameters: 30mm Dia Up to 260mm Dia

- Shaft Lengths: 300mm Up to 4000mm Length

- Static Balancing: Drive Drums are balanced as standard. Tail Drums are balanced on request.

- Dynamic Balancing: Specdrum has it’s own In-House Dynamic Balancing Machine. This saves money and time in production. Certificates of Dynamic specification achieved are also presented to our customer.

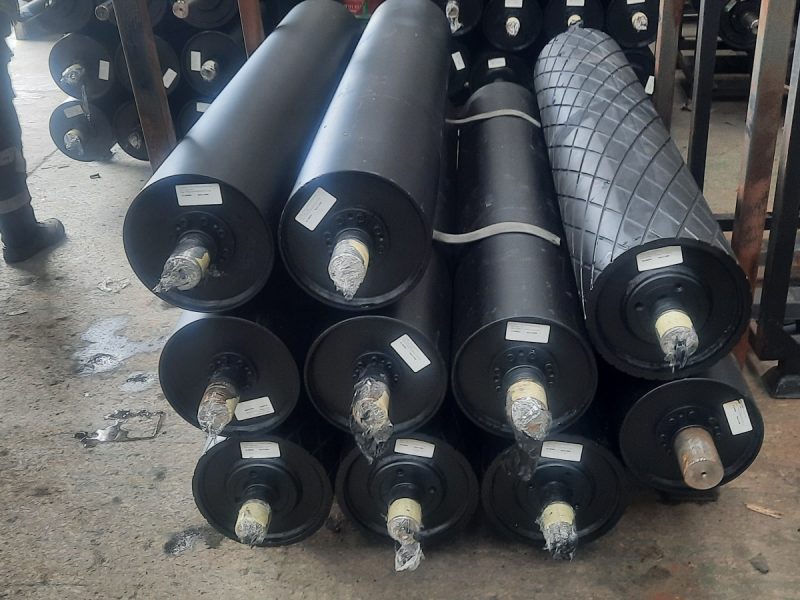

- In-House Rubber Lagging: Our own Autoclave oven means we can Hot Vulcanise the required rubber lagging onto Drums to your specified thickness and we can Groove the Drum also as specified on your Drawings. Having this manufacturing capability, in our own factory allows us to offer better pricing, improve lead times and control quality of the finalproduct.

“Our objective is to understand your Drive and Tail Drum requirements for all the Belt Conveyors your business manufactures”

JP O’Neill – Sales & Marketing Manager

Manufacturing Capacity – Excess of 75,000 Drums per year

Specdrum have a new 40,000 Sq Ft New Factory – which is dedicated to Drive and Tail Drum manufacture.

Within our factory in Mid-Ulster, we manufacture over 35,000 Drums annually and we have room for added capacity to grow the business further.

China – Specdrum also have a China manufacture facility. We bring in, store and distribute approximately 40,000 Drums per year for exiting customers. We visit our China Factory regularly and guarantee these to the same quality standards to represent the Specdrum brand.

Technical Reviews

We will Technically Review the Drum Drawings and advise of our manufacturing capability to meet the requested, specifications, dimensions, and tolerances.

Our Production Manager, Quality Manager, Estimating and Purchasing Team will all meet to discuss our respective details in relation to you Technical Drawings, so we can provide a comprehensive proposal and quote to you.

Consultative Process

Specdrums process is to meet and consult with you, understand your technical requirements, make a commercial agreement and ensure we delivery the correct Quantity and specification of each Drum, directly in to your factory floor.

Our mantra is DIFOTIS. Delivery In Full, On time, In Specification.

We understand that price is all important – however this must be matched with a Quality manufactured Drum.

Delivery In Full, On time, In Specification (D.I.F.O.T.I.S)

We do this by organising our production schedule to ensure we make scheduled, on time deliveries, directly into your factory warehouse, in time for your business to complete its production and delivery obligations to your valued customers.

Specdrum are highly experienced in providing this service for OEM’S located around the world who have Belt Conveyors as part of their final product solution to their Customer.

- Aggregates Material Handling – Mobile (Tracked or Wheels) Crushing, Screening, Trommels

- Recycling – Mobile (Tracked or Wheels) Shredders, STAR Screens, Trommels

- Agriculture – Mobile and Static Belt Conveyors for Vegetables, Spreading, Waste formation