Specdrum have the ability to use various forms of Shaft locking mechanisms in order to hold the shaft in place within the pulleys.

Welded Shaft

The Shaft can be welded into the End Plate of the Drum. Many of our Customers specify this method of ‘Shaft Locking’ as reliable method of Drum construction

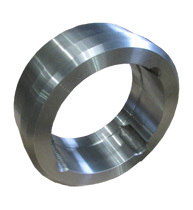

Keyless Locking Device:

Specdrum use various brands of Keyless Locking Devices – Bikon, Sati, Ringfeder

Keyless Locking Mechanisms offer simple installation, increased shaft strength and high torque transmission capacity.

The Shaft is also removable. This means should there be any break-down with the Shaft or bearings – Only the Shaft needs replaced. The Pipe and End Plates can remain in place,

Often reducing down-time and provides the opportunity to get the Conveyor up and going again quickly.

Main Advantages

- Standard Designs

- Eliminates the necessity of a keyway (Required in a Taperlock Bush & Hub system)

- Extensive bore range: 20mm and upwards

- Performs highly at transmission high torques

- Good resistance to alternating torques

- Operator-friendly installation and disassembly

- Eliminates fretting corrosion

Keyed Locking Mechanisms (Taperlock – Hub & Bush – Keyed):

Keyed Locking Mechanisms (Taperlock – Hub & Bush – Keyed):

Taperlock – Hub & Bush: are machined to precise tolerances therefore ensuring that they perform to the highest level.

Taperlock – Hub & Bush: Mechanisms used in the manufacturing of our pulleys in both Ireland and China, and provide a great level of reliability and strength.

Available in both metric and imperial sizes.

We use high quality machined Weld-On Hubs in tandem with our Taperlock Bushs in order to ensure the best outcome for our clients.

Main Advantages

- Easy to install and remove

- Full range in both metric and imperial sizes

- Complete short reach range available, for compact lightweight assemblies

- Our Weld-On Hubs have a machine-shouldered outer diameter, thus allowing for easy location